Adroit Engineering

Maximize your wind turbine's potential.

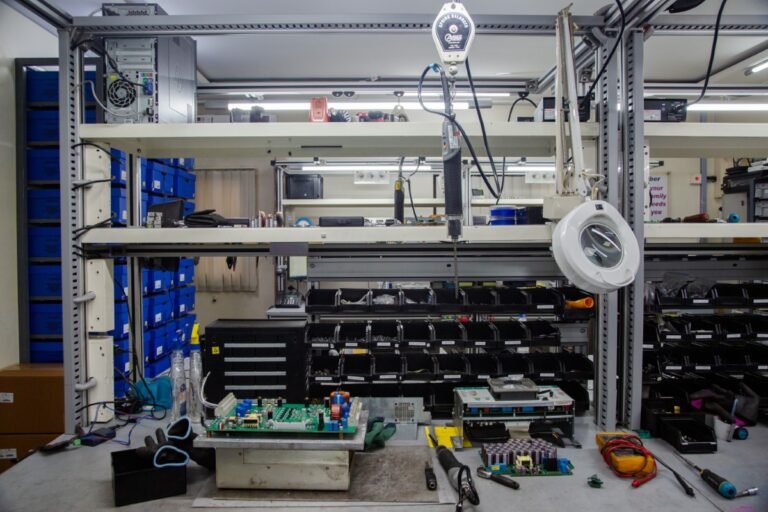

Adroit Engineering was established in 2012 with a focus on providing maintenance and repair services for wind farms. Our team of experts has years of experience in the wind energy industry and uses the latest tools and technology to deliver high-quality services. We recognize that wind farms can be intricate and require specialized attention, which is why we offer a comprehensive service model that covers all aspects of wind turbine maintenance. Our services include troubleshooting, repairs, preventative maintenance, and on-site inspections, ensuring that your wind turbines operate efficiently and seamlessly.

10+ years of service

ISO certified

70k+

parts repaired

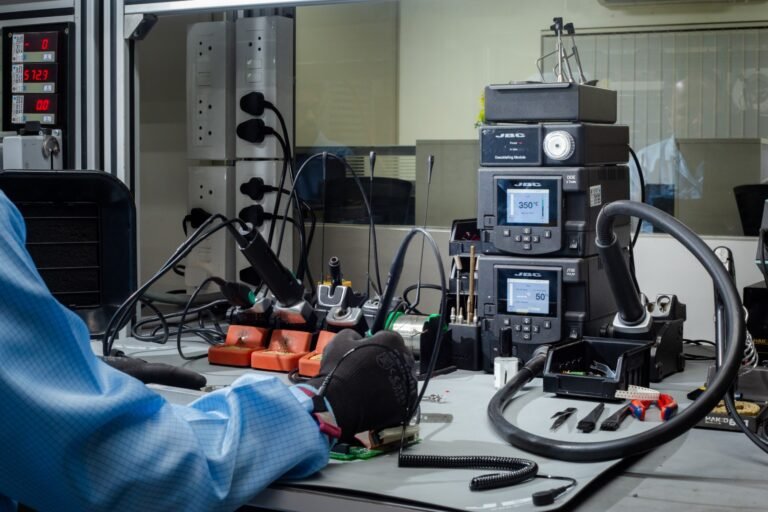

ESD standard test labs & German tools

Service plans that suit your needs.

Our services are designed to cater to your unique wind turbine maintenance needs. We offer tailored services, providing you with maximum value and cost-effective solutions. Our advanced diagnostics, comprehensive maintenance range, quick delivery, top-of-the-chain quality parameters, and high emphasis on safety standards have already made us the preferred choice of many of the biggest brands in wind energy. Connect with us to discuss how you can get the maximum energy output at the lowest possible cost.

Our services

Flexible, customizable, and comprehensive wind operations services

At Adroit Engineering, we offer holistic services to keep your wind farms running at maximum efficiency. We partner around the world with corporations of all sizes, offering tailored solutions to meet their unique needs.

Routine maintenance

Ensure smooth functioning of your wind turbines with visual inspection, oil and lubrication, debris removal, bolt, fasteners, and wiring inspection.

Preventive maintenance

Minimize the risk of downtime and ensure uninterrupted operations and optimal performance. Includes inspection and repair of rotor, gearbox, electrical system, brakes, pitch, and yaw system.

Component replacement

Replace worn-out components with new ones and continue to get superior performance from your wind turbines.

Emergency repairs

Get immediate repair and minimize the downtime for unexpected failures and breakdowns, such as gearbox failures, electrical issues, or structural damage.

Safety systems

Ensure compliance with safety regulations with optimal performance of the safety systems like emergency stop systems, overheating protection, and grid failures.

Cleaning and de-icing

Dirt, debris, and ice build-up can reduce the efficiency and damage components. Get your blades and other surfaces cleaned for ideal performance.

Data analysis

Make sense of the data. Utilize data from condition monitoring systems and sensors to identify potential issues before they lead to major failures.

Remote monitoring and diagnostics

Get your wind turbines monitored remotely and avoid major failures and downtime. Get a predictive analysis of wind turbines’ health, increase energy production, and make operations efficient.